煤矿开采

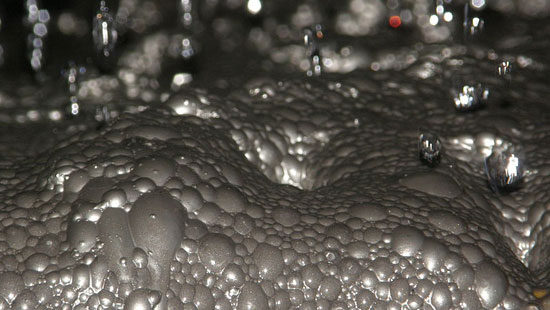

达到回收率和质量KPI对煤矿开采至关重要。除了总体目标之外,煤炭处理和选煤厂(CHPP)的经营者还在不断优化浮选流程,以提高损失煤的回收率。管理环境影响也同样重要,因此拥有了解整个流程细微差别的经验丰富的合作伙伴是必不可少的。

纳尔科可以帮助您更有效地管理煤炭浮选,同时满足规格要求并保护环境。CoalEX™和Nalflote™ “粉煤”方案提供绿色聚集剂、起泡剂、过滤和助滤剂,以帮助优化回收率并满足质量规格要求。DustBan®和EliminIce™方案可促进安全环保的固体处理,而Pol E-Z®、WaterShed™和EnAct®将加快高效的水资源循环利用,以帮助保护生态系统并协助实现合规性。

我们团队的技术专长可以帮助您大大提高浮选动力学,解决煤炭分选问题,同时满足经济和环境目标。

Flotation 360™

矿物加工优化就像瞄准一个移动的目标。不同的矿石、不适当的配方或未能平衡回收率和品位都可能影响您的经营业绩。但纳尔科拥有适当的解决方案:Flotation 360。这项数字技术可以帮助您充分提高生产效率,优化浮选流程的效能。

利用Flotation 360的预测能力优化您的流程,帮助:

- 改善性能,提高回收率和盈利能力

- 增强可见性,以便针对未来矿石变化的潜在影响,提前缓解任何挑战

- 优化试剂用量和化学品消耗,降低总体运营成本

- 减少维护难题(如浮选槽阀门故障),减少人工排除故障的时间

煤矿开采产品

对用于煤矿开采的起泡剂或捕收剂感兴趣?了解纳尔科如何帮助您满足回收率和品位目标,从而提高效率并达到关键绩效指标。

起泡剂

捕收剂

相关解决方案

了解纳尔科的矿业解决方案,包括磷酸盐开采和加工助剂。