产品级晶圆抛光液

数十年来,纳尔科一直在为晶圆行业提供硅溶胶。凭借全面而广泛的专业技术,我们能够生产出业内最高质量的硅抛光液。

我们高度稳定的硅溶胶产品具有卓越的纯度,以及可控的粒径、分布和形态,可在您的产品级晶圆抛光工艺流程中实现最佳性能。

精心设计晶圆抛光液以实现:

高去除率

稳定的性能

低缺陷率

优异的表面光洁度和平坦度

用于硅晶圆抛光的即用型硅溶胶浆料

- 粒径(nm): 60

- pH值: 11

- 稳定添加剂:无+

- 粒径(nm): 60

- pH值:8.5

- 稳定添加剂:无+

- 粒径(nm): 85

- pH值:11-12

- 稳定添加剂:NH4

- 备注:螯合添加剂

- 粒径(nm): 85

- pH值:11-12

- 稳定添加剂:NH4

- 备注:高硅去除率。危险。

- 粒径(nm): 120

- 面积(m2/gm): 25

- 固体百分比: 47%

- pH值:9-10

- 稳定添加剂:K+

应对多种抛光应用

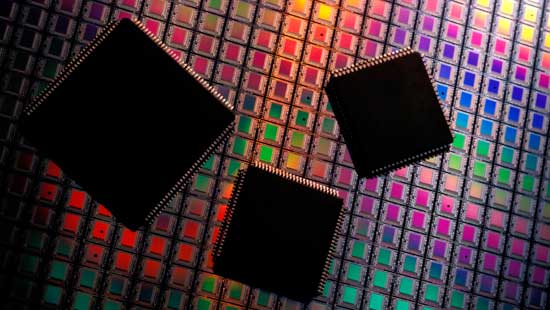

我们的硅溶胶抛光液广泛用于硅晶圆及其他微芯片半导体衬底生产中的原材料抛光、边缘抛光和末道抛光工序。

此类抛光液还可用于对光学器件、钟表玻璃及其他玻璃元件的表面进行精密加工。

针对CMP浆料配方设计师的需求进行创新

纳尔科已针对CMP浆料配方设计师的需求,对我们的硅溶胶生产能力进行了调整,以提供高纯度的创新纳米颗粒。

- 基于水玻璃的超高纯度纳米微粒

- 各类颗粒尺寸、粒径分布及浓度

- 可在广泛的pH范围内保持性质稳定的工程产品

- 密切的研发合作关系

纳尔科是硅溶胶领域的领先企业

- 在1941年率先获得专利的硅溶胶制造工艺

- 全球最大的硅溶胶制造商之一

- 从事定制产品开发并注重创新的研发和工程团队

- 专为改进生产效率、质量和控制而设计的产品

- 通过创新的颗粒设计和质量,实现卓越价值

参考资料

- 产品采用LMSII工程方法制成,可去除铜和镍等金属至20 ppb以下。供货情况取决于订购量。↵