矿物加工助剂

优化您的矿物加工作业

纳尔科是全球领先的矿物加工试剂和解决方案提供商。我们服务于不同的市场,积累了数十年经验,在全球拥有1,600多名研究、开发和工程人员。我们的全球化业务布局及专业知识助力我们提供从矿山到工厂的技术、经济和环境可持续的矿物加工解决方案。

我们多样化的矿物加工助剂产品组合涵盖众多应用,包括流变改性剂、助滤剂、晶体生长调变剂、液体稳定剂、草酸盐稳定剂以及腐殖质去除剂。通过解决采矿工艺流程的优化问题,纳尔科可以帮助您最大限度地提高生产效率和产量,并对您的利润产生积极影响。

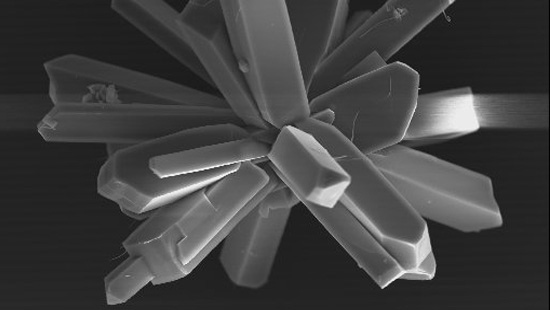

聚焦:晶体生长调变剂

在竞争激烈的氧化铝精炼环境中,加工厂一直面临着提高产量,同时保持水合物晶体尺寸和质量的挑战。纳尔科提供专为用于拜耳法沉淀循环而设计的晶体生长调变剂(CGM)。该方案加强了对团聚和成核机制的控制,这可以对最终产品尺寸控制、液体产率、水合物分类和草酸盐干扰控制产生积极影响。

晶体生长调变剂只是纳尔科广泛的矿物加工助剂产品中的一种。联系我们,讨论您的具体运营需求并详细了解我们的矿物加工解决方案。

Flotation 360™

矿物加工优化就像瞄准一个移动的目标。不同的矿石、不适当的配方或未能平衡回收率和品位都可能影响您的经营业绩。但纳尔科拥有适当的解决方案:Flotation 360。这项数字技术可以帮助您充分提高生产效率,优化浮选流程的效能。

利用Flotation 360的预测能力优化您的流程,帮助:

- 改善性能,提高回收率和盈利能力

- 增强可见性,以便针对未来矿石变化的潜在影响,提前缓解任何挑战

- 优化试剂用量和化学品消耗,降低总体运营成本

- 减少维护难题(如浮选槽阀门故障),减少人工排除故障的时间

矿物加工助剂成功案例

晶体生长调变剂方案推动氧化铝工厂改善效率、可持续性、性能和成本

在地中海的一家氧化铝工厂,企业社会责任在其日常运营中发挥着重要作用。着眼于安全性、最佳资源利用和最大程度地降低成本,该工厂寻求新的有效方法来提高整体工艺流程的效率。在与该工厂开展合作的过程中,纳尔科确定运用晶体生长调变剂可以帮助推动该工厂取得理想的成果。

下载案例分析,了解纳尔科的晶体生长调变剂方案如何通过提高盈利能力和降低成本,每年帮助创造超过743,000欧元的价值。

推动全球矿物加工创新

纳尔科非常重视研发和创新。为解决各种矿物加工挑战,我们组建了一支由化学家和工程师组成的专业团队,以推动我们在全球范围内以客户为本的技术研究中心的发展。从美国到澳大利亚西部、从荷兰到印度西部乃至世界各地,纳尔科提供全球化的专家团队,他们了解您工厂当地的情况,并能敏锐地意识到可能影响您运营的区域性挑战。

纳尔科矿物加工助剂

这种分散剂是一种低分子量的水性配方,专门设计用于包含高钙盐流程的矿物加工应用,作为有效的分散剂和阻垢剂 。分散剂的作用是降低矿浆的粘度。它还可以改变晶体结构,从而改变积垢的性质和速度。

- 改善矿浆的流变性。

- 清洁矿物表面,从而提高有价值的矿物的采收率。

- 对于严重的结垢问题,可以降低积垢的速度。

- 防止有价值的矿物产生矿泥罩盖。

- 不起泡特性。

- 高温下稳定。

| 产品 |

|---|

| NALFLOTE 600-05 |

Filtermax脱水助剂主要用于精矿的过滤,以降低滤饼的水分含量,改善滤饼的处理特性。其作用是降低水的表面张力,更重要的是,可以使矿物颗粒表面更疏水(拒水),从而进一步降低水分含量。

- 减少滤饼中的水分,降低干燥和运输成本。

- 加快过滤速度,从而降低过滤器的资本投资。

- 更好的滤饼剥落性能,可提高过滤器的效率。

- 减少滤布阻塞,提高滤布使用寿命。

| 产品 |

|---|

| FILTERMAX 470LV |

| FILTERMAX 440GFM |

产品、设备和服务

了解我们的矿物加工助剂产品组合

我们找不到与以下关键词匹配的结果:“".